Context

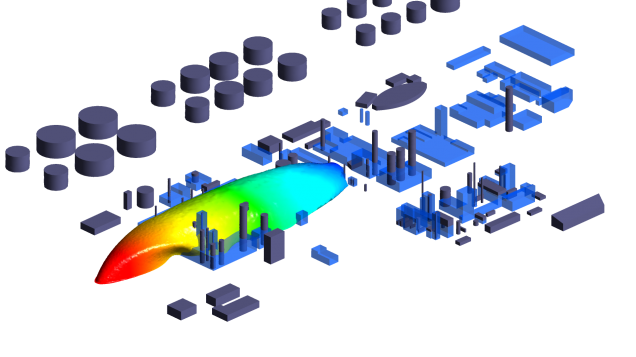

In chemical production units, the reactor is often the central element of the process. The term “reactor” itself actually covers a wide variety of different systems: tubes, open or closed tanks, furnaces, columns, boilers, etc. What they have in common is that they enable chemical transformation, and they differ in how they work to achieve this.

Reactors are classified as single-phase or multi-phase (gas/liquid, fluid(s)/solid), batch or continuous, isothermal or adiabatic, tubular or perfectly stirred, among other categories. These reactors are used in the chemical and process industries, as well as in pharmaceuticals, water treatment, cell culture, and biofermentation.

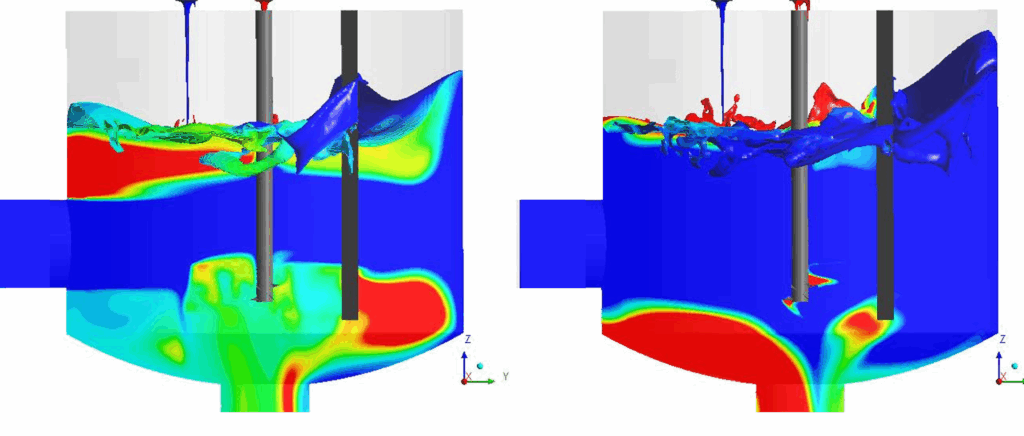

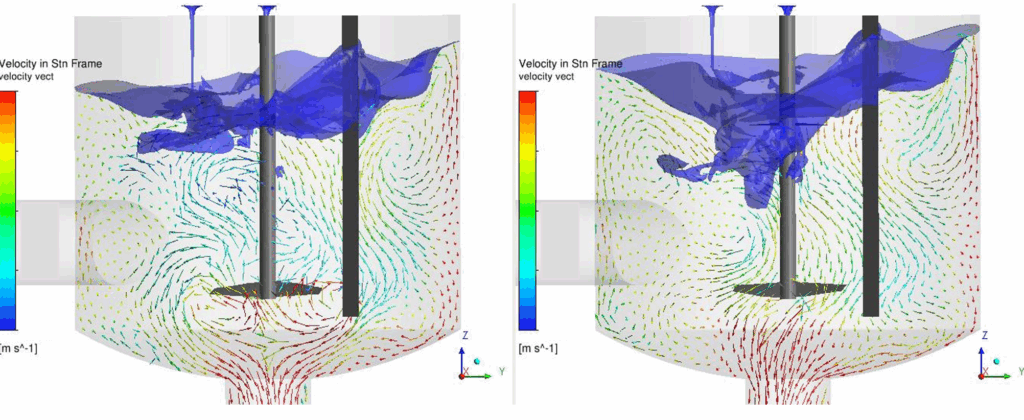

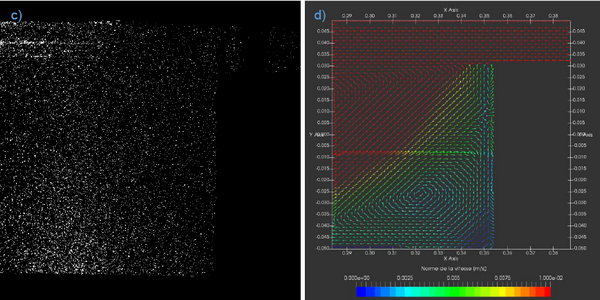

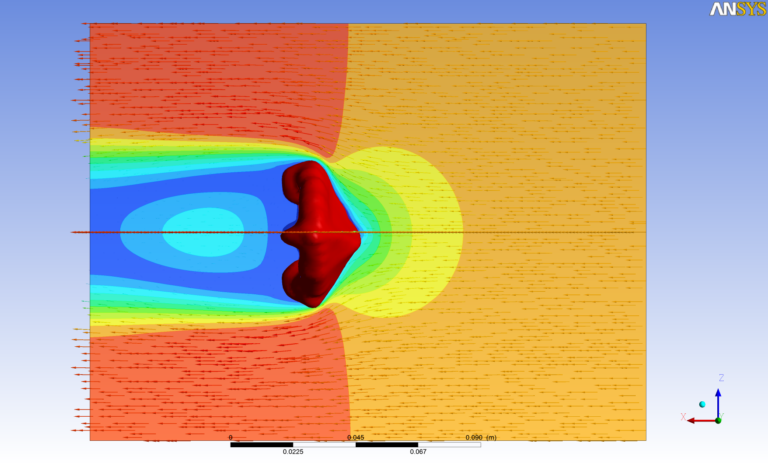

In this example we are looking at a continuous stirred tank reactor. This tank allows a high flow rate of circulating acrylonitrile to come into contact with sulfuric acid.

Acrylonitrile is a liquid monomer that is widely used in the plastics industry, particularly in the manufacture of nylon, synthetic rubber, and ABS (Acrylonitrile Butadiene Styrene).

The sulfuric acid, also in liquid form, is injected from the top of the reactor, causing a jet phenomenon that impacts the free surface of the mixture.

The vessel is also equipped with baffles, which generate an axial/radial mixture.